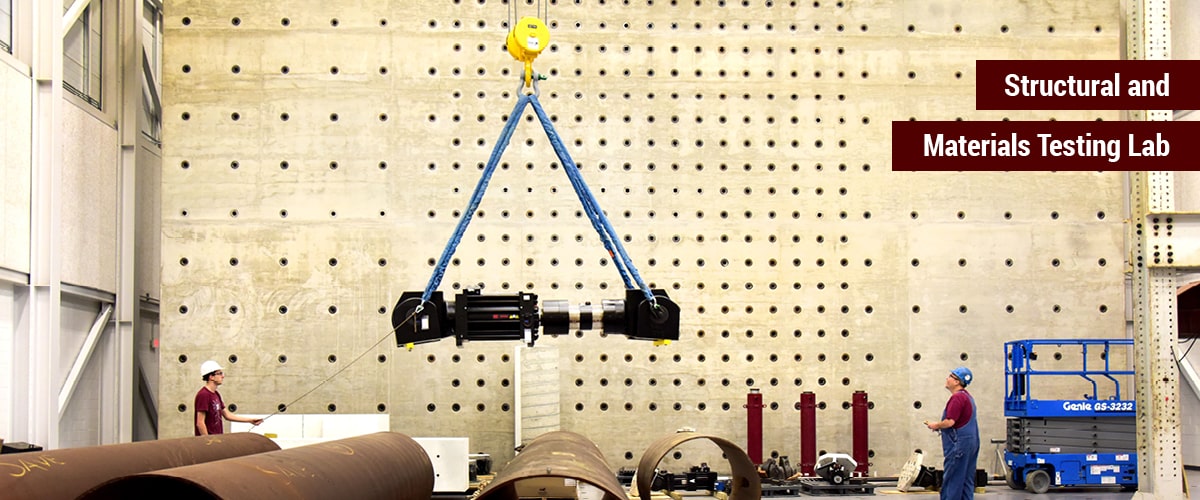

Comprehensive Material Testing Lab

Wiki Article

Mechanical Checking Center: Reviewing Product Efficiency

Are you curious concerning just how materials are evaluated for their performance in engineering? In this article, we will certainly discover the relevance of product testing and also the different mechanical tests used to evaluate product efficiency.Value of Material Testing in Engineering

You need to recognize the relevance of product testing in engineering to make certain the efficiency as well as reliability of your products. Material screening is a critical action in the style and production process. By subjecting materials to various examinations, you can examine their mechanical residential properties as well as determine if they fulfill the needed standards as well as specs.

Material testing likewise allows you to guarantee the dependability and also long life of your items. By simulating real-life conditions and subjecting materials to extreme temperature levels, moisture, and corrosive environments, you can evaluate their toughness and also efficiency with time. This aids you make educated decisions about the materials you choose for your products, avoiding potential failures and also pricey recalls in the future.

Furthermore, product testing offers important data that can be used to improve the design and production procedure. By analyzing the results of different tests, you can maximize the product choice, recognize areas for improvement, and boost the overall high quality of your products.

Kinds Of Mechanical Examinations for Assessing Product Performance

When it comes to assessing material efficiency, there are a number of types of mechanical examinations that can be performed. One typical test is the tensile examination, which determines the toughness as well as ductility of a material by using stress until it damages. One more test is the compression examination, which examines a material's capability to endure compressive forces.

Recognizing Product Residence for Testing

When you are assessing product efficiency in a mechanical testing facility, it is crucial to have a comprehensive understanding of the different homes that can influence the material's habits. Stamina is typically measured with examinations such as stress or compression examinations, where the material is subjected to pulling or pressing pressures until it reaches its breaking point.One more crucial property is hardness, which refers to the material's resistance to imprint or damaging. This home is critical in determining the material's ability to endure deterioration. Firmness can be determined making use of numerous approaches, consisting of the Brinell or Rockwell hardness tests.

Furthermore, it is very important to think about the material's ductility, which is its capability to go through plastic deformation without fracturing. Ductility is measured through tests like the tensile examination, where the material is stretched until it reaches its snapping point. This residential or commercial property is particularly essential in applications where the material requires to be curved or developed without breaking.

Equipment and also Methods Utilized in Mechanical Evaluating

To accurately assess the residential or commercial properties of different products, it's vital to acquaint yourself with the equipment as well as techniques used in mechanical screening. One of the most generally made use of pieces of equipment is the global testing machine. This device applies regulated forces to test the toughness, elasticity, and various other mechanical residential properties of materials. It is composed of a tons framework, grips, and a control board. By readjusting the holds and also setting the wanted pressure, you can test numerous specimens. An additional crucial tool is the hardness tester, which gauges the resistance of a material to impression. There are different sorts of hardness testers, such as Rockwell, Brinell, and also Vickers, each using a various method to figure out hardness. Along with these machines, there are different techniques utilized in mechanical screening. Tensile testing, from this source for instance, involves extending a material till it breaks to determine its toughness and flexibility. Compression screening, on the various other hand, includes using pressures that squeeze the material to gauge its strength as well as security. By understanding the devices and also techniques utilized in mechanical testing, you can properly evaluate the performance of various products.Interpreting and also Studying Examination Outcomes for Product Efficiency Analysis

When translating and analyzing examination outcomes, you'll need to carefully examine the information to determine just how well the products carry out. These could show prospective issues or inconsistencies in the product's performance.Next, think about the particular residential or visit this page commercial properties go right here being examined and also contrast them to the desired requirements or criteria. Are the results within the appropriate array? If not, it is essential to identify the reasons behind any kind of discrepancies. This could include examining the screening approach, example preparation, or also the material itself.

Final thought

There you have it, understanding the relevance of product testing in design is important for evaluating product performance. With the appropriate devices and strategies, you can precisely gauge as well as analyze examination results to analyze material efficiency.Report this wiki page